| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Certification : ISO, UL, IPC, Reach

MOQ : 1

Payment Terms : T/T

Supply Ability : Post-soldering 700,000 points/day

Delivery Time : 5-30 days

Layer : 2-36 Layer

Material : FR4

Board Thickness : 0.2-10mm

Surface Finish : Immersion Gold

Pin Space : 0.2mm

Application : Medical

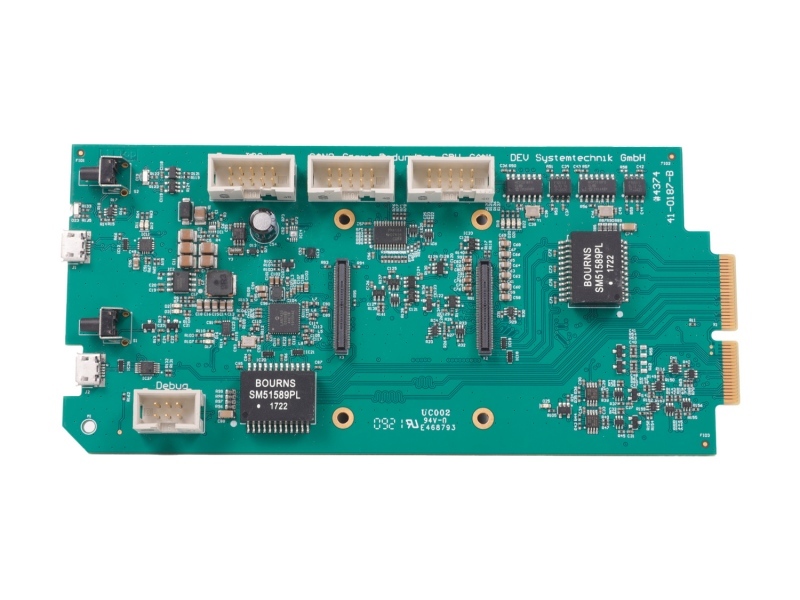

Customised Medical PCB Assembly with UL Certificate

♦ What Is PCB Assembly Service?

PCB Assembly Service refers to the process of assembling electronic components onto a printed circuit board (PCB) to create a functional electronic device. It involves several stages, from sourcing components to soldering and testing the final product.

♦ Key Steps in PCB Assembly:

PCB Fabrication:

Component Sourcing (Procurement):

Solder Paste Application:

Pick-and-Place Machine:

Reflow Soldering:

Through-Hole Component Insertion (if needed):

Wave Soldering (for THT):

Inspection & Testing:

Final Cleaning & Packaging:

DQS Electronic Group is one of the leading EMS company in China, we provide PCB design, PCB manufacturing, PCB assembly service and testing. Welcome send us your Gerber file to get free quotation. Our email: sales@dqspcba.com

♦ Technical Parameters

| PCB Assembly Capability | |||||

|

Item |

Normal |

Special | |||

|

SMT Assembly |

PCB(used for SMT) specification | Length and Width( L* W) | Minimum | L≥3mm, W≥3mm | L<2mm |

| Maximum | L≤800mm, W≤460mm | L > 1200mm, W>500mm | |||

| Thickness( T) | Thinnest | 0.2mm | T<0.1mm | ||

| Thickest | 4 mm | T>4.5mm | |||

|

SMT components specification | Outline Dimension | Min size | 0201(0.6mm*0.3mm) | 01005(0.3mm*0.2mm) | |

| Max size | 200 * 125 | 200 * 125 | |||

| component thickness | T≤15mm | 6.5mm<T≤15mm | |||

| QFP,SOP,SOJ (multi pins) | Min pin space | 0.4mm | 0.3mm≤Pitch<0.4mm | ||

| CSP/ BGA | Min ball space | 0.5mm | 0.3mm≤Pitch<0.5mm | ||

|

DIP Assembly |

PCB specification |

Length and Width( L* W) | Minimum | L≥50mm, W≥30mm | L<50mm |

| Maximum | L≤1200mm, W≤450mm | L≥1200mm, W≥500mm | |||

| Thickness( T) | Thinnest | 0.8mm | T<0.8mm | ||

| Thickest | 3.5mm | T>2mm | |||

|  |  |  |

|  |  |  |

2. Quality Guaranteed:

3. Premium Service:

|

|

Customised Medical SMT PCB Manufacturing PCBA oem UL Certificated Images |